Safe towing depends significantly on the trailer plug and socket. These small but crucial components ensure that lighting, braking, and signal transmission between your trailer and vehicle are in good working order. Over time, wear and tear, corrosion, or injury can compromise their operation, putting your safety and goods at risk. In this guide, we discuss the five most typical trailer plug issues, step-by-step repair and troubleshooting instructions, and why an upgrade to quality اذهب مقطورة products can provide you with long-term peace of mind.

Common Trailer Plug Problems

Lights Not Working

If your turn signal, brake lights, or rear lights fail to illuminate when plugged in, it’s a clear sign of a connection issue. Corroded pins or frayed wires inside the plug or socket are the usual culprits.

Flickering or intermittent power

Dancing lights or lights that work only when the plug is wiggled indicate an uneven connection. Worn-out pins, loose innards inside the wiring, or poor contact inside the socket are the usual reasons.

Visible Corrosion on Pins

Corrosion on metal pins is from exposure to seawater, road salt, or coastal atmospheres. Corrosion adds more electrical resistance and will even cause a break in continuity.

Loose or Unstable Connection

If the trailer plug does not engage correctly or gets pulled out during travel, this will cause loss of power to brake lights or signals, which is a significant safety concern.

Bent or Damaged Pins

Physical damage is common, especially if the plug is frequently connected and disconnected. Bent or broken pins may not align with the socket, causing incomplete connections.

How to Troubleshoot Trailer Plug Issues

Before replacing your trailer plug or socket, try these simple checks:

- Inspect Plugs and Sockets

Disconnect the trailer and examine both ends with a flashlight. Look for dirt, rust, melted plastic, or bent pins.

- Check Continuity

Measure continuity between every pin on the trailer plug and every trailer wire with a multimeter. There will be no continuity with broken interior wires.

- Check for Short Circuits

Measure resistance from every pin to ground. Minimal or zero resistance where there should be zero indicates there’s a short circuit that needs fixing.

DIY Trailer Plug Repair Tips

All trailer plug problems are capable of being fixed with a few tools and effort.

- Cleaning Corroded Contacts

Clean wires with an electrical contact cleaner or a wire brush to eliminate pin oxidation. Dry thoroughly before reassembling.

- Repairing Loose Wires

If there are loose wires within the plug housing, disassemble the plug and resecure them tightly. Screw terminals or solder are good.

- Straightening or Replacing Bent Pins

Distorted pins can be straightened using needle-nose pliers. Defective pins must be replaced for proper connection.

- Repairing Short Circuits

Pinpoint faulty wires by checking continuity between each wire and ground. Replace damaged areas with new outdoor-rated insulated cable.

Replace with Go Trailer Products

When repairs are not up to code, using superior-quality parts guarantees smooth operation in the long run.

Why Choose Go Trailer Plugs and Sockets

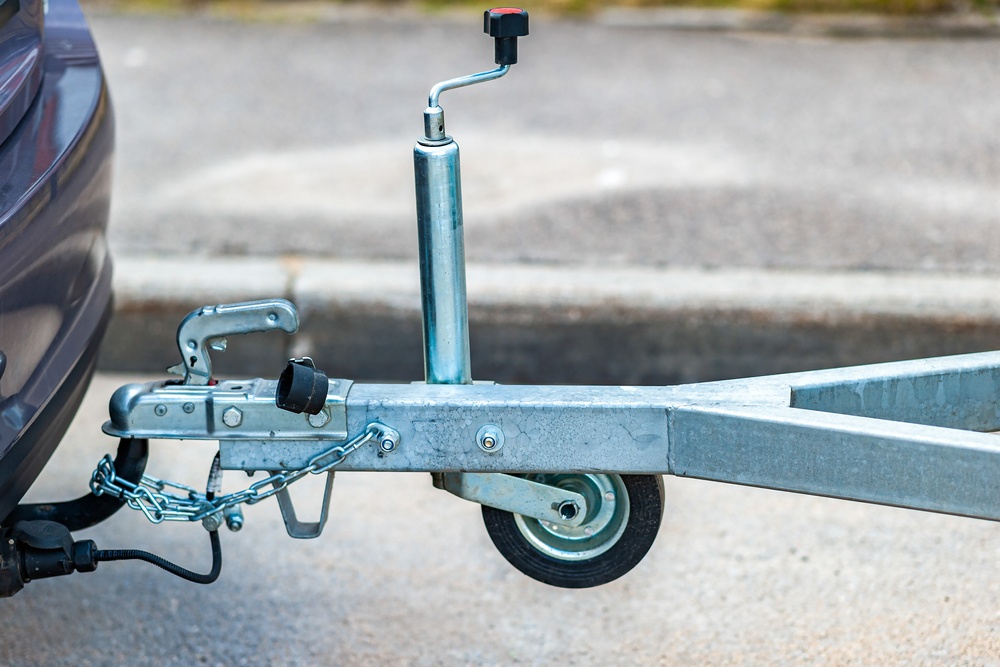

Go Trailer, Qingdao, China, has been producing trailer parts, such as jockey wheels, winches, couplers, and electrical items, for more than 15 years. Our plug and socket are made to:

- Resist corrosion with a protective coating.

- Seal firmly against vibration-induced disconnection.

- Comply with CE safety regulations.

- Guarantee a smooth power supply to all light systems.

How Go Trailer Solves Common Problems

Our products fix the day-to-day aggravation of trailer electricals: loose contacts, corrosion, and pin damage. For boat trailers, ATVs, and cargo trailers, Go Trailer plugs and sockets deliver consistent performance in demanding conditions.

Maintenance Tips for Extended Life

To achieve maximum benefit from your trailer plug and socket system—particularly if you’ve upgraded with Go Trailer components—maintenance is the factor:

Regular Inspection Schedule

Perform visual inspections before each trip. Inspect for wear signs such as cracked casings or frayed cables that could compromise performance during transit.

Good Storage Practices

Avoid leaving exposed plugs when not in use, cover them up with weather-proof caps, and keep connectors away from the ground where dirt and grime can accumulate.

Winter Maintenance Checklist

After winter storage or following extended exposure to saltwater (maintenance with boat trailers), scrub thoroughly and lubricate with dielectric grease to avoid corrosion accumulation.

خاتمة

Whether it’s coping with flickering lights, loose wiring, or adding a long-term upgrade, these troubleshooting procedures and Go Trailer top-level spares guarantee safe, reliable towing. Simple inspection, proper servicing, and spending money on heavy-duty plugs and sockets are the secrets to having your trailer’s electric system in top shape.

FAQ

Q: Can I obtain spares from Go Trailer?

A: Sure, no issues—we can do sample service along with full orders based on your requirements.

Q: Do your plugs work outside?

A: The product is universal and will both function indoors and outdoors with no problem at all.

Q: How long does shipping take?

A: Orders are usually processed and shipped within 5-10 business days, although expedited shipping can be accommodated at your request.

Q: What if my product is defective?

A: Our post-sales service policy includes immediate action on customer complaints regarding quality—repair or replacement based on problem severity.