تضمن مقرنات المقطورة اتصالات آمنة يمكن الاعتماد عليها بين المركبات والمقطورات. صناعة القطر الأمريكية تتوسع. ينبع هذا النمو من ارتفاع الاحتياجات للسحب الترفيهية والتجارية والصناعية. نتيجة لذلك ، تغيرت مقرنات المقطورة بشكل كبير. لقد انتقلوا من التصميمات الأساسية إلى النماذج المتقدمة والمبتكرة. تستكشف هذه المدونة كيف تطورت مقرنات المقطورة. كما أنه يغطي الاتجاهات الحالية التي تشكل السوق. بالإضافة إلى ذلك ، فإنه يشارك ما يجب أن يعرفه مراوح القطر والمهنيين للبقاء محدثين.

تاريخ موجز من مقرنات المقطورة

التصميمات والوظائف المبكرة

ظهرت مقرنات المقطورة الأولى في أوائل القرن العشرين. كانت بسيطة ومصنوعة من الصلب المزور. استخدمت هذه المقرنات نظام كرة ومقبس أساسي لربط المقطورات بالمركبات. ركزوا على الوظيفة بدلاً من المرونة. في كثير من الأحيان ، كانوا يحتاجون إلى تعديلات يدوي وعملوا مع عدد قليل من كرات العقبات. على الرغم من أنها مفيدة في ذلك الوقت ، إلا أن مقرنات المقطورة المبكرة تفتقر إلى سلامة اليوم وراحة.

توحيد في منتصف القرن العشرين

بحلول الخمسينيات من القرن الماضي ، اتخذت صناعة القطر خطوات كبيرة في توحيد الأجزاء. تضع مجموعات مثل جمعية مهندسي السيارات قواعد لأحجام كرة العاتين وتصنيفات المقرنة. جعل هذا المقرنات المقطورة أكثر توافقًا عبر المركبات. خلال هذا الوقت ، أصبحت مقرنات الصلب المختوم شائعة. كانت أخف وزنا وأرخص من المزورة. هذه التغييرات جعلت السحب أسهل لمزيد من الناس ، مثل المزارعين والمخيم.

التحول نحو السلامة والمتانة

كانت السلامة أيضًا ذات أهمية قصوى خلال أواخر القرن العشرين. ظهرت مقرنات مقطورة الأقفال المضافة لتجنب التفكك العرضي. كما استخدمت الشركات مادة مقاومة للصدأ ، والتي شملت طلاء الزنك والصلب المجلفن. جعلت هذه الابتكارات مقرنات أقوى وأكثر موثوقية للاستخدام. تم تقديمها لأغراض عطلة نهاية الأسبوع والتجارية.

الابتكارات الحديثة في تصاميم مقرنة المقطورة

ميزات السلامة المحسنة

مقرنات مقطورة اليوم بنيت مع السلامة أولا. عرض التصميمات الحديثة:

- أنظمة القفل التلقائي: هذه قفل المقرنة إلى كرة العوائق دون جهد يدوي. أنها تقلل من الأخطاء.

- آليات مضادة للوصول: هذه الاستقرار في المقطورات أثناء محركات الأقراص السريعة أو الطقس عاصف.

- المؤشرات البصرية: بعض المقرنات لها علامات مشفرة أو متوهجة. يظهرون ما إذا كان الاتصال آمنًا ، مما يساعد في الليل.

هذه الميزات تتبع قواعد السلامة الأمريكية الصارمة. أنها تضمن الامتثال لأساطيل الأعمال والراحة للمستخدمين العاديين.

التطورات المادية

تحسنت المواد الموجودة في مقرنات المقطورة بشكل كبير:

- سبائك قوية: هذه خفيفة ولكنها صعبة. أنها تتعامل مع الأحمال الثقيلة دون وزن إضافي.

- الطلاء مقاوم للصدأ: التشطيبات المجلفنة والمغطاة بالمسحوق تحمي من التآكل. أنها تناسب المناطق الساحلية أو الرطبة.

- المواد المركبة: بعض الشركات تختبر المركبات لمقانين خفيفة الوزن. هذه رائعة للمقطورات الأصغر ، مثل تلك الخاصة بـ ATVs أو UTVs.

ترقيات المواد هذه تعزز المتانة والأداء. يلتقيون احتياجات القطر المختلفة.

تكامل التكنولوجيا الذكية

التكنولوجيا الذكية تغير مقرنات المقطورة. بعض النماذج الحديثة تشمل:

- أجهزة استشعار تحميل: هذه تحذير السائقين من وزن غير متساو أو الزائد. أنها تساعد في منع الحوادث.

- اتصال Bluetooth: صلة المقرنات الذكية بتطبيقات الهاتف. أنها تظهر البيانات في الوقت الفعلي ، مثل محاذاة عقبة أو ارتداء.

- أنظمة القفل الكهربائية: هذه تستخدم طاقة السيارة للقفل عن بعد أو فتح. أنها تجعل العقبات أسرع.

تجذب هذه الميزات المستخدمين المحبين للتكنولوجيا الذين يريدون الراحة والقطر القائم على البيانات.

الاتجاهات الرئيسية التي تشكل سوق مقرنة مقطورة الولايات المتحدة

الطلب على مقرنات المقطورة الشاقة

ترى صناعة القطر الأمريكية الحاجة المتزايدة إلى مقرنات مقطورة شاقة. هذه المقبض الأحمال أكثر من 10000 رطل. يأتي هذا الاتجاه من:

- نمو الأعمال: الحقول مثل البناء والخدمات اللوجستية والزراعة تحتاج إلى مقرنات قوية للمعدات الثقيلة.

- RV شعبية: ارتفاع التخييم في RV يزيد الطلب على المقرنات التي تدير المقطورات الكبيرة بأمان.

توفر المقرنات الشاقة ، مثل تلك القابلة للتعديل أو المتعددة الموضع ، المرونة. أنها تتناسب مع كل من النقل المحترفين وعشاق RV.

التصنيع الصديق للبيئة

استدامة أشكال الإنتاج مقرن المقطورة. يستخدم المصنعون الآن:

- مواد قابلة لإعادة التدوير: الصلب المعاد تدويره والألمنيوم أقل ضرر بيئي.

- طرق لتوفير الطاقة: الأنظمة الآلية ، مثل تصنيع CNC وقطع الليزر ، تقلل من النفايات.

- الطلاء الأخضر: الطلاء القائم على الماء قطع الانبعاثات مقارنة مع المذيبات القائمة على المذيبات.

هذه الممارسات تروق للمشترين الوعائيين. كما أنها تطابق أهداف الاستدامة العالمية.

التخصيص والتنوع

التخصيص هو الاتجاه الصاعد. تقدم الشركات المصنعة مقرنات مقطورة مصممة لتلبية احتياجات محددة:

- مقرنات قابلة للتعديل: هذه التبديل بين أحجام كرة السقوط أو ارتفاعات القطر.

- تصميمات متخصصة: مقرنات لمقطورات القوارب لديها حماية إضافية للصدأ لبيئات المياه.

- خيارات العلامات التجارية: يمكن للشركات إضافة لوحات مخصصة. هذا يجذب تجار الجملة وتجار التجزئة.

يضمن هذا التركيز على المرونة أن يقرن المقطورات تلبي متطلبات المستخدم الفريدة.

مقارنة أنواع مقرنة المقطورة الشائعة

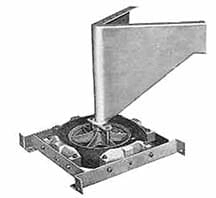

| نوع مقرنة | حمولة حمولة أقصى | الميزات الرئيسية | الأفضل ل |

| قناة مستقيمة مقرنة | ما يصل إلى 5000 رطل | تصميم بسيط ، بأسعار معقولة | مقطورات الضوء ، ATVS |

| A-Frame anjoper | ما يصل إلى 14000 رطل | قوي ، يتعامل مع الأحمال الثقيلة | RVS ، مقطورات البضائع |

| مقرن قابل للتعديل | ما يصل إلى 20،000 رطل | مواقع متعددة ، مرنة | المعدات التجارية والثقيلة |

| Rososeneck jopler | ما يصل إلى 30،000 رطل | قوية جدا ، مثالية للمقطورات الكبيرة | الثروة الحيوانية ، المقطورات الصناعية |

يوضح هذا الجدول مجموعة متنوعة من مقرنات المقطورة. إنه يساعد المستخدمين على اختيار أفضل واحد لمهام القطر الخاصة بهم.

لماذا تختار Go Trailer لمقربات المقطورة

كمورد كبير في صناعة القطر ، اذهب مقطورة يوفر مقرنات مقطورة عالية الجودة. مقرها في تشينغداو ، الصين ، تتمتع Go Trailer بأكثر من 15 عامًا من الخبرة في صنع أجزاء المقطورة. نحن نقدم العديد من المقرنات ، بما في ذلك تصميمات مقطورة A-Frame و Adlemable و Tover. أدواتنا المتقدمة ، مثل تصنيع CNC وقطع الليزر ، تضمن الجودة. فحوصات جودة صارمة تأكد من أن كل مقرنة تلبي معايير CE. GO TRAILER القيم السلامة ، التخصيص ، والممارسات الخضراء. وهذا يجعلهم خيارًا موثوقًا به لتجار الجملة وتجار التجزئة وصانعي المقطورات في الولايات المتحدة وأستراليا وأوروبا.

الأسئلة الشائعة حول مقرنات المقطورة

س 1. ما هو الفرق بين القناة المستقيمة ومقننة مقطورة الإطار A؟

A1. مقرنة مقطورة قناة مستقيمة أبسط وأخف وزنا. إنه يعمل مع مقطورات أصغر مع أحمال تصل إلى 5000 رطل. مقرنة A-Frame لها شكل ثلاثي. وهو يدعم أحمال أثقل تصل إلى 14000 رطل. إنه لأمر رائع بالنسبة لمقطورات RVS ومقطورات الشحن.

س 2. كيف يمكنني الحفاظ على مقرن المقطورة الخاص بي لضمان طول العمر؟

A2. قم بتنظيف المقرنة بانتظام لإزالة الأوساخ. تزييت الأجزاء المتحركة للحفاظ عليها ناعمة. تحقق من الصدأ أو التآكل في كثير من الأحيان. استخدم رذاذ مقاوم للصدأ لحمايته ، وخاصة في البيئات الصعبة.

س 3. هل يمكن استخدام مقرنات المقطورة بأحجام كرة عقبة مختلفة؟

A3. نعم ، تعمل مقرنات مقطورة قابلة للتعديل بأحجام كروية مختلفة. هذه تتراوح من 1-7 /8” إلى 2-5 /16”. تحقق دائمًا من مواصفات المقرنة لتأكيد التوافق.

س 4. ما هي ميزات السلامة التي يجب أن أبحث عنها في مقرنة مقطورة؟

A4. اختر مقرنات مع أقفال تلقائية لمرفق آمن. تساعد الميزات المضادة للسيرة أثناء محركات الأقراص الطويلة أو السريعة. تظهر المؤشرات المرئية ما إذا كان الاتصال آمنًا. هذه تحسين السلامة السحب.

دعوة إلى الإجراء: ترقية تجربة القطر الخاصة بك

لقد تطورت مقرنات مقطورة بشكل ملحوظ. استكشاف أحدث تقنية مقرنة المقطورة. ابحث عن المباراة المثالية لاحتياجاتك. يزور GO TRAILER'S ANOLER COLLEST لرؤية خيارات عالية الجودة. تحقق من مقرنات A-Frame ، مقرنات قابلة للتعديل ، وغيرها من مقرنات المقطورات. هل أنت مستعد للسحب بشكل أفضل؟ الاتصال GO TRAILER اليوم لتعزيز إعداد القطر الخاص بك!