Introduction: The Silent Danger Beneath Your Trailer

Think about heading along a major road with a heavy trailer hooked up. Out of nowhere, smoke starts rising from one of the trailer’s wheels. Once that burnt grease smell hits you, the harm is usually done for good. Trailer Hubs and Bearings handle the tough jobs quietly on every haul. They bear the full load of whatever you carry and let the wheels roll with little resistance. Yet when these parts break down, the trouble goes beyond a stalled trip. Serious axle damage or a lost wheel can happen. Figuring out what leads to high heat forms the starting point for safer driving and longer part life, and it is exactly where Remolque focuses its engineering attention.

Understanding the Mechanics: How Trailer Hubs and Bearings Work Together

Stopping problems start with knowing how the hub and bearings fit together. The trailer hub attaches the wheel firmly. Bearings, often tapered roller kinds, go inside the hub. They allow smooth spinning around the fixed axle spindle.

- The Hub: Holds grease and protects the bearing races.

- The Bearings: Include inner and outer pairs made to manage straight-down weight and side pushes from corners.

- The Seal: Locks grease in and keeps out water, plus road dirt from the delicate bearing area.

All pieces working right keep the friction very small. When something throws that off, movement changes to heat quickly. Metal parts then wear out in no time.

Primary Causes of Overheating and Failure

Inadequate or Contaminated Lubrication

Grease keeps Centro de remolques and Bearings running. It forms a tiny layer between rollers and races so metal stays apart.

- Grease Breakdown: Heat over long periods thins grease and lets it drip away, drying out the bearings.

- Water Contamination: Boat owners see this a lot. Dipping a warm hub into cold water pulls moisture inside through suction. Rust follows, grinding bearing faces like rough grit.

Mechanical Overloading and Stress

Each trailer carries a set weight limit. Going past that squeezes the bearing rollers too much.

- Flattening the Rollers: Heavy extra loads can squash rollers a tiny bit. Turning becomes rough, raising drag.

- Heat Accumulation: Bearings under too much weight heat up faster than the hub can cool. Temperature climbs, parts swell, and friction grows worse in a bad loop.

Improper Bearing Adjustment and Installation

Settings need to fall in the middle range – neither too tight nor too slack.

- Too Tight: A spindle nut pulled too hard leaves no room for heat growth. Strong pressure brings quick heat as driving starts.

- Too Loose: Extra movement makes the hub shake. Bearings wear unevenly, and the grease seal can break, letting dirt back in.

Warning Signs Every Operator Should Know

Catching issues early avoids major fixes. Trailer owners ought to look out for these signals regularly:

- Abnormal Noise: Sharp chirps, rough grinding, or low hums from wheels point to missing grease or scarred bearing races.

- Vibration: Shakes passing to the tow vehicle often mean the hub spins off-center.

- Physical Heat: After a brief trip, feel the hub middle by hand. Warm is normal; burning hot is not.

Go Trailer Solutions: Engineered for Thermal Stability and Durability

At Go Trailer, we run a focused manufacturing operation in Qingdao, China, with more than 15 years of experience building reliable trailer pieces. Our Trailer Hubs and Bearings start from tough steel shaped on up-to-date machines like CNC tools and laser cutters. Each item follows strict ISO9001 quality rules.

High-Performance Lazy Hubs

For trailers without brakes, our lazy (idler) hubs give a light but sturdy choice.

- Versatile Fitment: Comes in 4-stud and 5-stud setups with PCDs from 100mm to 114.3mm and 150mm.

- Load Capacity: Made to support 1000kg to 1500kg per pair, keeping things steady for many utility uses.

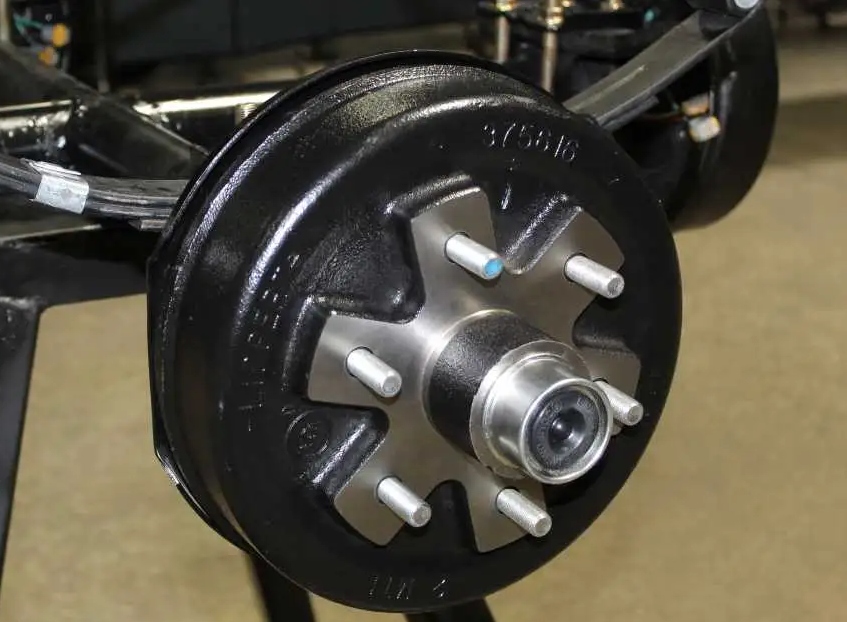

Robust Drum Hubs for Braking Systems

Nuestro drum hubs link up easily with brake units and release heat well.

- Specifications: Supplied in 5-stud and 6-stud forms (for example, PCD 120.0mm or 139.7mm) to suit different axles.

- Durability: Built strong to take the added heat from hard braking stops.

Precision-Engineered Disc Hubs

Where water and salt pose risks, like on boats, our disc hubs stand as the smarter pick.

- Corrosion Resistance: Offered with galvanized or electrophoresis coatings against rust.

- Stability: Include PCDs such as 114.3mm and 139.7mm, taking loads up to 1500kg.

The Advantage of Customized Hub Systems

Off-the-shelf pieces do not suit every special job. Go Trailer puts effort into custom options for customers. From odd stud layouts to particular sizes or special coatings, our trained staff builds what you need.

Our custom features cover:

- Material Selection: Choose tough steel or lighter aluminum alloy based on load and weather needs.

- Surface Finishing: Pick galvanized, painted, or electrophoresis layers to stand up to rough settings.

- Technical Precision: We craft hubs from your drawings or OE numbers for an exact match.

Dealing straight with Go Trailer skips dealers. You cut time and costs while getting a part shaped for your exact trailer.

Conclusion: Prevention Through Quality Components

Breakdowns in Trailer Hubs and Bearings can almost always be stopped with steady care and solid parts. Knowing the key reasons for heat – bad grease, excess weight, or wrong setup – lets you act ahead. Picking Go Trailer brings a partner devoted to safe travel, strong builds, and straightforward dealings.

A trailer holds up only as well as its tiniest turning pieces. Wait no longer for smoke signals. Pick carefully made hubs and bearings ready for long hauls.

FAQ

Q: How often should I check the grease in my Trailer Hubs and Bearings?

A: It is recommended to inspect your hubs and bearings at least once a year or every 10,000 miles. For boat trailers frequently submerged in water, more frequent inspections are necessary to check for moisture contamination.

Q: Can Go Trailer provide hubs for specific international standards?

A: Yes. We manufacture parts that meet European, Australian, and American standards. We offer various stud patterns and PCD sizes to ensure compatibility with global axle specifications.

Q: What should I do if my hub feels excessively hot after a drive?

A: Pull over immediately and allow it to cool. Excess heat usually indicates a lack of lubrication, an over-tightened spindle nut, or a bearing that has already begun to fail. Do not continue driving as this could result in the wheel seizing.

Q: Does Go Trailer offer customized stud patterns for unique trailer builds?

A: Absolutely. We provide a comprehensive, customized service where we can manufacture hubs according to your technical drawings, samples, or specific material preferences to ensure they meet your unique requirements.