Is your trailer’s taillight system failing? Whether you’re preparing for a trip or on the road, malfunctioning lights are more than an inconvenience—they’re a safety hazard. Understanding common issues can help you quickly diagnose and fix the problem. In this guide, we cover the six most common reasons why trailer taillights stop working and provide step-by-step instructions to get them shining again.

1. Burned-Out Bulbs

Warning Signs Your Trailer Bulbs Are Burned Out

The simplest issue is most often a burned-out bulb. The most obvious indications are:

- One or both taillights are completely dark.

- The lights flash on and off.

- Running lights fail to illuminate, but brake or turn signals still work.

How to Check and Replace a Bulb

Tools You’ll Need:

- Screwdriver (type depends on your light housing)

- Replacement bulb (ensure correct type and voltage—check your trailer manual)

- A clean cloth or gloves (to avoid touching the new bulb with bare hands)

Step-by-Step

- Always start by disconnecting the trailer from the tow vehicle to avoid any electrical shock or short circuits.

- Remove the lens cover. The majority of trailers contain screws and clips to retain the cover in place.

- Examine the bulb. A colored glass or broken filament means the bulb needs replacing.

- Install the new bulb with care, without touching the glass portion of the bulb with your fingers. Which leads to hotspots and shorten the life of the bulb.

- Replace the lens cover and have the trailer up and running again. Inspect all the light parts before driving.

2. Corroded Light Connectors

Why It Happens

Trailer lights are subject to constant careening through the environment of water, dust, road salt, and other corrosive agents. Over time, these agents produce oxidation on metal connectors, which slows down electricity flow. This is most common with boat trailers or those in wetter climates.

How to Check

Disconnect the trailer plug and carefully inspect the vehicle- and trailer-side connectors. Look for white or green crusty material, rusty or tinted pins, or rust.

Replaces Corroded Connectors

Clean terminals with electrical contact cleaner and a wire brush. Allow them to dry, then lightly coat them with dielectric grease to future-proof against water. For future-proofing long-term, replace with sealed connectors or waterproof LED lights, such as those offered by GO Trailer.

3. Bad Ground Connection

The Grounding Function

Ground connection completes the electric circuit. When corroded or loose, your lights will be erratic—flicker, function intermittently, or not at all.

Locating the Ground Wire

The ground wire tends to be white and ought to be held securely to the trailer frame, generally near the coupler.

Repairing a Defective Ground:

- Determine where the ground is bolted.

- Remove any rust, paint, or grime near the connection with sandpaper or a wire brush.

- Reconnect the ground wire using a star washer to bite into the metal so that it has a good hold.

- If the problem persists, add an independent ground wire from each light back to the master ground point.

4. Blown Fuses

How Fuses Affect Trailer Lights

Fuses are meant to safeguard your vehicle’s and trailer’s electrical systems against overloads. Blowing a single fuse renders the whole lighting circuit useless.

Finding and Checking Fuses

Consult your tow vehicle’s owner’s manual to locate the fuse box (most commonly under the hood or dash). Look for fuses labeled “Trailer,” “Aux,” or “Towing.” Check for continuity with a multimeter or test light. Replace shorted-out fuses with new ones of the same amperage. Warning!If the new fuse blows immediately, there may be a wiring short circuit that can best be repaired by a professional.

5. Loose Connectors or Bad Wiring

Typical Wiring Problems

Trailer wiring is subject to vibration, wear and tear, UV exposure, and occasional chewing by animals. Wires may become loose, frayed, or pinched, too, with the passage of time.

Visual Inspection Tips

Very carefully follow the wiring harness from the connector to all the lights. Look for cracked insulation, exposed wire, or loose fittings. Check closely where wires pass through the trailer frame or are exposed to the weather. Gently wiggle connectors to ensure that they are seated properly. For those who heavily utilize their trailers in harsh environments, it is more than worth the money to spend the cash on a premium, abrasion-proof wiring kit by GO Trailer and avoid a headache down the line.

6. Troublesome Switches or Controls

When the Problem Is with the Tow Vehicle

If all of the trailer parts check out, then the problem may be with your tow vehicle. New vehicles are equipped with advanced modules to operate lights, and these modules do fail.

How to Troubleshoot

With a multimeter, check the voltage on the vehicle’s 7-pin or 4-pin connector when an assistant uses the headlights, brake pedal, and turn signals. If there is no voltage on the applicable pins, the problem is probably in the vehicle’s wiring, switch, or tow module.

Preventive Maintenance Tips to Prevent Future Issues

- Perform Periodic Checks

It is recommended to check all lights and connections before each journey. Look for moisture on lenses and corrosion on contacts.

- Upgrade with Tough Parts

Waterproof LED lights, weather-tight junction boxes, and rust-resistant connectors are well worth the expense. Companies such as GO Trailer are experts at designing parts with toughness in mind for harsh conditions.

- Apply Protective Products

Apply dielectric grease freely to all electrical connections to keep out moisture.

- Seal All Wiring

Conduit and zip tie wires to shield from vibration and wear.

How to Find Long-Lasting Replacement Parts

For dependable lighting, wiring, and connectors, use GO Trailer. We specialize in manufacturing high-quality, compliant trailer parts. Our product line includes:

- Durable, waterproof LED taillightassemblies

- Sealed junction boxes and harnesses

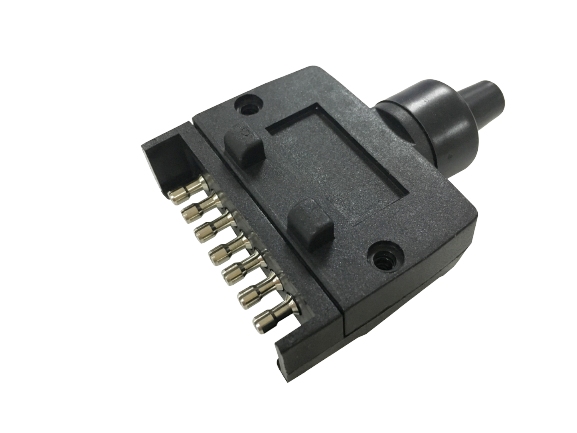

- Corrosion-resistant plugs and sockets

Buying directly from the factory ensures that you get long-lasting parts that are designed to perform under real usage conditions without the dealer’s profit markup. Shop with us today and make your next tow safe and reliable.

FAQ

Q: Why do my trailer lights flash on periodically but not constantly?

A: This is almost always the result of a loose or corroded connection, most often the ground. Inspect all connections for cleanliness and tightness.

Q: Can I put any bulb on my trailer lights?

A: No. Only the bulb specified by your light housing manufacturer should be used. The wrong bulb will lead to poor performance, electrical issues, or damage.

Q: My turn signals are blinking rapidly, but the brake lights are functioning properly. What is wrong?

A: This is typically an issue on a single side of the trailer—a bad turn signal bulb blown on one side. It could also be a loose connection or incorrect (e.g., LED) bulbs installed without the included flasher relay.

Q: Is LED superior to incandescent for trailer lights?

A: Yes, overall. LEDs consume less power, are shock-resistant, and last much longer. They are less likely to fail due to vibration. Most importantly, they are sealed, so they are waterproof and will not corrode.

Q: The tester shows that my car plug is good, but won’t allow my trailer lights to function. What do I do?

A: The issue is certainly on the trailer. Start by checking the ground connection to the trailer frame, as it’s the most common point of failure. Second, check the entire wiring run for cracks or damage.

Q: What are the ways I can prevent corrosion on my trailer’s electrical equipment?

A: Clean connectors from time to time and put a dielectric grease coat on them. When replacing parts, use sealed and rust-resistant parts such as GO Trailer’s parts, which are built for marine and off-road use specifically.